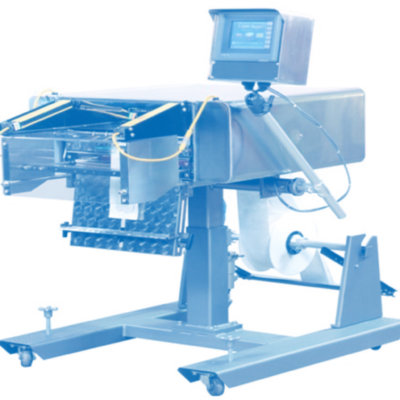

Our bag filling machine can be integrated into your existing line in the best possible way and automate your packaging process. Semi-automatic bag filling machines and semi-automatic fillers can also increase your production efficiency and provide you with consistent, high quality packaging. Our bag filling equipment has proven to be very fast and user-friendly, meeting diverse bagging needs across various industries.

The bag filling machine is simple and straightforward. The required bags are hung and printed with basic data. Thanks to innovative technology, changes to print jobs can also be easily adopted without interrupting the packaging process. Whether you need an open mouth bag filler or a valve bag system, our equipment adapts to your specific requirements.

The “Plug & Pack” system inflates the bag, thus facilitating the actual filling process. The filling process can be carried out manually by employees or through fully automated systems. This flexibility ensures that businesses of all sizes can benefit from our packaging solutions.

Precision and Speed Hallmarks of Our Cutting-Edge Bag Filling Systems

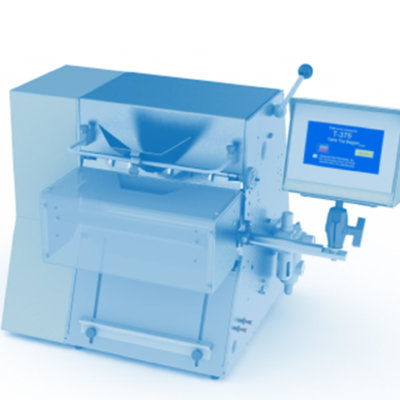

Our cutting-edge bag filling systems represent the pinnacle of precision and speed in packaging technology. We’ve engineered these bag filling machines to meet the demanding needs of modern production lines, where accuracy and efficiency are paramount. By incorporating advanced sensors and control mechanisms, our bag filler units achieve unparalleled consistency in fill weights, reducing product waste and ensuring compliance with regulatory standards.

The speed of our automated bag filling machines is equally impressive. High-performance motors and optimized filling mechanisms allow for rapid cycle times, significantly boosting throughput. Our high-speed filling equipment can handle everything from free-flowing granular products to fine powder materials. This increased productivity translates directly to improved operational efficiency and cost-effectiveness for your business. Moreover, our bag filling equipment is designed with scalability in mind, enabling seamless integration into existing production setups.

Durability is another key feature of our bag filling and sealing machines. Constructed from high-grade materials and built to withstand continuous operation, these machines offer exceptional longevity. Each filling station is engineered for maximum reliability, whether processing dry bulk products or handling delicate materials. User-friendliness is a core principle in our design philosophy. Intuitive interfaces make our automatic bag fillers accessible to operators of all skill levels. Our automatic pouch filling machine models feature the same user-centric approach, ensuring smooth operation across all equipment types.

Why Industry Leaders Choose Our Bulk Bag Filling Equipment

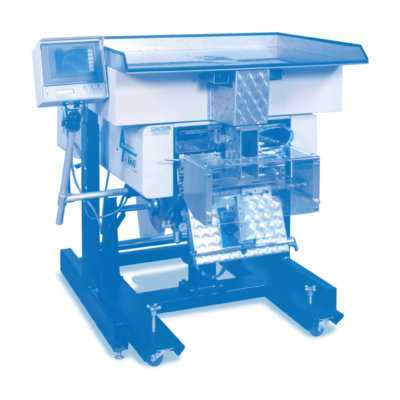

Industry leaders consistently select our bulk bag filling equipment for its unmatched combination of reliability, versatility, and innovation. We’ve developed our bulk bag filling machine technology with a deep understanding of the diverse challenges faced by various industries, from agriculture to chemicals and beyond. This insight allows us to offer bagging solutions that not only meet but exceed the expectations of even the most demanding clients.

Adaptability is a key factor that sets our bag loading machines apart. We recognize that different products require different handling approaches. That’s why our filler equipment is designed with modular components and adjustable parameters, allowing for quick customization to suit specific product characteristics. Whether you need a pouch filling machine or a bulk bag filler system, our solutions provide the flexibility required for optimal performance across a wide range of materials, from fine powders to coarse granules.

The robust construction of our auto bag filling machines is another reason for their popularity among industry leaders. We use high-quality materials and precision engineering to create machines that stand up to the toughest industrial environments. This durability translates to less downtime, lower maintenance costs, and excellent return on investment. Our equipment integrates seamlessly with conveyor systems and robotic palletizers to create complete packaging solutions. As a leading manufacturer and supplier, we continuously invest in research and development to incorporate the latest technological advancements, including fill and weigh capabilities and integrated quality control measures.

Choosing the Right Bag Filling Equipment for Your Needs

Selecting the appropriate bag filling equipment for your specific requirements is crucial for optimizing your packaging process. We offer a comprehensive range of solutions, from manual bag fillers for smaller operations to fully automatic bag filling machines for high-volume production lines. Understanding your unique needs is the first step in identifying the ideal equipment for your business, and our team works closely with you to determine the best bagging solutions.

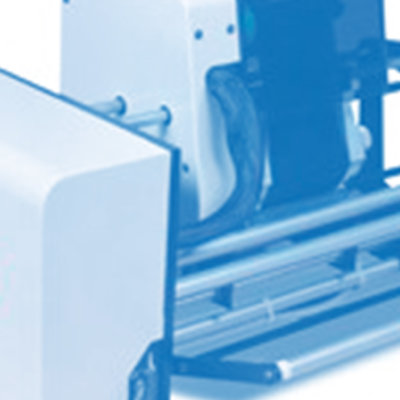

Production volume is a key consideration when choosing bag filling equipment. For businesses with lower output requirements, our manual bag filling machines offer a cost-effective solution without compromising on accuracy. The pouch filling machine price varies depending on specifications and automation level, ensuring options for every budget. For medium to high-volume operations, our automatic bag filling machines deliver exceptional efficiency and consistency. These systems can handle a wide range of bag types and sizes, with features such as automatic bag placement, bag flattening mechanisms, and integrated sealing. Our packing and filling machine solutions incorporate advanced features like vibratory feeders and impeller systems for consistent material flow.

Product characteristics play a significant role in equipment selection. Our bag filling systems are designed to handle various materials, from free-flowing granules to cohesive powders. We offer specialized features such as densification systems for powder filling applications, controlled feed rates for delicate products, and dust extraction systems for cleaner operations. Whether you need open mouth bag or valve bag technology, we match these features to your product’s properties, ensuring optimal performance throughout the entire filling and sealing process.

Enhance Product Quality Through Precision Bag Filling Machines

Precision bag filling machines play a crucial role in enhancing product quality across various industries. Our advanced bag filling machines for sale are engineered to maintain the highest standards of accuracy and consistency throughout the filling process. This precision not only ensures that customers receive exactly what they pay for but also helps preserve the integrity of the product itself. Each bag filler is calibrated to deliver precise results, whether handling bulk materials or smaller package sizes.

One of the key features of our bag filling equipment is its ability to control fill weights with exceptional accuracy. Advanced weighing systems, coupled with intelligent control algorithms, allow for real-time adjustments during the filling process. This level of precision minimizes overfilling and underfilling, reducing waste and ensuring compliance with weight regulations. Our automatic bagging machines incorporate sophisticated sensors that monitor every fill cycle to maintain consistency. Product degradation during the filling process is addressed through gentle handling mechanisms and controlled flow rates, with specialized filling nozzles that minimize product breakage.

Contamination control is another aspect where our precision bag filling machines excel. We incorporate features such as enclosed filling chambers, dust extraction systems, and easy-to-clean designs to maintain a hygienic filling environment. Our pouch filling and sealing machine models feature sealed environments that protect products from external contaminants. The equipment seamlessly integrates with conveyor systems to ensure smooth material transfer throughout your facility, essential for meeting regulatory standards in food and pharmaceutical packaging.

From Concept to Reality Customized Bag Filling Systems for Your Needs

Transforming concepts into reality is at the core of our approach to creating customized bag filling systems. We understand that every business has unique requirements, and off-the-shelf solutions may not always suffice. Our team of experienced engineers works closely with clients to develop tailored bag filling equipment that perfectly aligns with their specific operational needs and goals. As a trusted pouch filling machine manufacturer, we bring decades of expertise to every project.

The customization process begins with a thorough analysis of your production requirements. We consider factors such as product characteristics, desired throughput, available space, and integration with existing systems. This comprehensive assessment forms the foundation for designing a bag filling solution that accommodates future growth and changes in your product line. Whether you require big bag filling capabilities for bulk materials or a compact pouch filler for smaller packages, we engineer solutions that optimize your operations.

Flexibility is a key feature of our customized bag filling systems. We design machines that can handle multiple bag sizes and types, allowing for easy product changeovers and reducing downtime. Our pouch filling and packing machine designs incorporate quick-change features that enable operators to switch between different products with minimal setup time. Throughout the development process, we leverage advanced technologies including IoT capabilities for real-time monitoring, advanced control systems for improved precision, and custom filling mechanisms. Our fully automated solutions can be equipped with bag sealer machine integration, automatic seal verification, and quality control checkpoints. The result is a system that fills bags with precision and consistency for both granule and powder applications.