Bags & packaging solutions for the cosmetics industry

Packaging plays an important role in the cosmetics industry. Packaging is not only important for the logistics processes and to protect the content, but especially for customers when making purchasing decisions. The choice of products for cosmetic products also depends a lot on the packaging design and overall appearance.

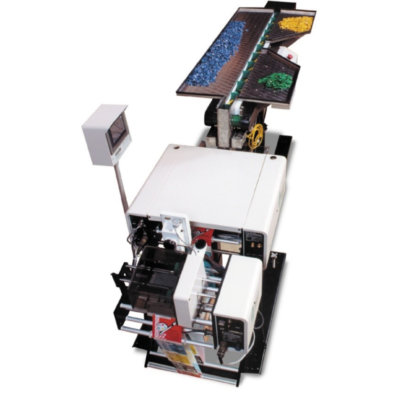

Set your products apart from the competition and secure increasing sales figures. Bagging machines for cosmetic industry – automatic.

Pouch/Bag packaging machines for the cosmetics industry

Packaging plays a very important role in the cosmetics industry. Not only that the products often have very different dimensions and sizes. Design also plays an enormous role for consumers in this industry. The decision in the store is largely determined by the packaging. The packaging therefore serves not only to protect, label and logistics, but in particular to influence the customer’s decision to buy. Bagmatic offers you, as a packaging machine manufacturer, tailor-made solutions, systems and comprehensive advantages for your applications:

- Durable products

- Quality material

- Flexible systems

- Innovative techniques

- Modernization options

- Comprehensive service

Packaging machines for the cosmetics industry

semi- or fully automatic – horizontal & vertical

pouch materials

Bagmatic offers variants:

- Foil pouch

- Flowfresh

- Foil bags

- Twinpacks

- Stretch film

- Doyback

pouch properties

- Different bag sizes

- Printed foils

- Fast warehouse sales

- High material quality

- Extravagant pouch properties possible

The BagMatic service for packaging machines cosmetics industry

Our services go beyond the actual products. Our trained employees support you in many areas:

- Maintenance & repairs

- Conception plans

- Assembly work

- Consultations

- Telephone hotline

- External sales

- Training for customers

Our concern is to offer packaging machines and solutions at a good price! We support our customers from the cosmetics industry in order to be able to offer automatic, fast and high-quality processes. Our extensive customer service makes us a unique provider of packaging machines.

– B. Norman Walter, Manager

Your advantages with Bagmatic and the packaging machines:

- A young, family-owned company in the third generation of packaging specialists

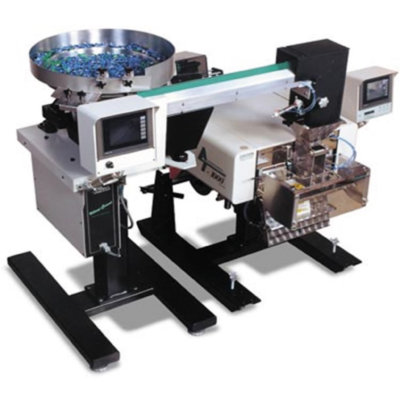

- Competencies in both semi-automatic and fully automatic packaging machines

- Unique "vision system" for quality control and accurate counting of products

- Camera solution for registering the parts to be packed before they are packed in bags

- Unique solution for counting and packaging very small and light parts, e.g. flower seeds

- Robot integration for fully automatic packaging (parts loading)

- Neutralization of static electricity of parts prior to packaging in bags

- Incomparably good customer service both in our house as well as with the customers on site Europe-wide

- Fair and competitive prices

- New and reconditioned machines in stock

Your advantages with Bagmatic and the packaging machines:

- Closing bags made of barrier material

- Closing bags made of polyethylene

- Transport packaging and industrial packaging

- Closing sterile goods packaging

- Welding tubular foils

- Filling and closing at the same time

- Promotional packaging

- Reduce transport volume or oxygen

- Testing flexible materials

Inquire now without obligation and let us advise you

Or direct phone call: 02631/4449000 or an E-Mail to info@bagmatic.com.

Packaging machine for the cosmetics industry for professional solutions

The cosmetics industry places special demands on packaging technologies. A professional packaging machine for the cosmetics industry must take both functional and aesthetic aspects into account. While the protection of sensitive cosmetic products is a top priority, visual presentation also plays a decisive role in sales success.

Modern packaging systems offer precise dosing and uniform filling of various cosmetic products. From liquid foundations to creamy lotions and powdery eye shadows, every product consistency requires specific packaging parameters. A cosmetic packaging machine not only ensures consistent quality, but also reduces product losses and optimises operating costs.

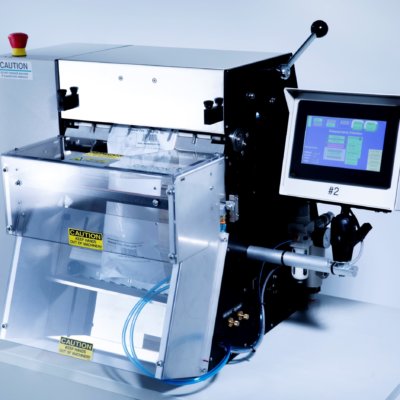

Hygiene standards play a central role in the selection of suitable packaging technology. Stainless steel components and easy-to-clean surfaces ensure the necessary cleanliness throughout the entire packaging process. These properties are particularly important as cosmetic products come into direct contact with the skin and must meet the highest purity requirements.

Modern cosmetic packaging machines increase your efficiency

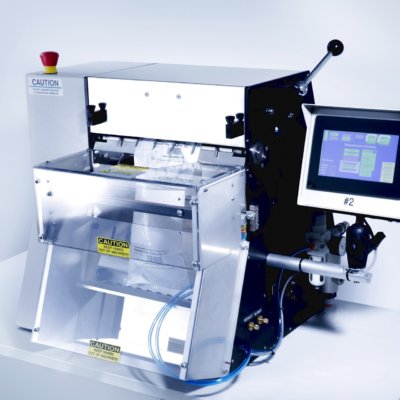

A modern cosmetic packaging machine transforms production processes through automated processes and intelligent control systems. Touchscreen control panels enable intuitive programming of different packaging formats and product specifications. This significantly reduces changeover times between different cosmetic items.

Precision dosing ensures that each packaging unit receives exactly the desired amount of product. Modern weighing systems continuously monitor the filling weight and automatically correct any deviations. Thanks to this technology, a packaging machine for the cosmetics industry minimises overfilling and ensures consistent product quality throughout the entire production batch.

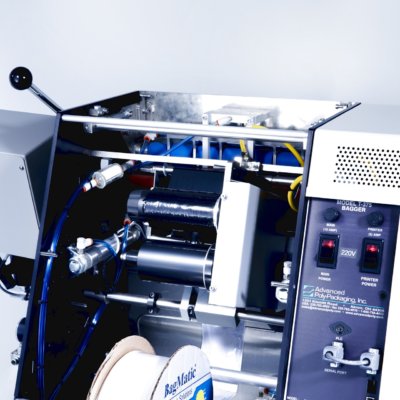

Production speed and energy efficiency go hand in hand in modern packaging systems. Servo drives and optimised motion sequences reduce energy consumption while achieving higher throughput rates. Maintenance-friendly designs reduce downtime and maximise system availability. Diagnostic systems detect potential problems at an early stage and enable proactive maintenance measures.

Flexible packaging machine for cosmetics for all product sizes

Flexibility in packaging different product sizes is a key success factor for cosmetics manufacturers. A flexible packaging machine for cosmetics adapts effortlessly to different container shapes and volumes. Adjustable guides and modular format parts enable quick adjustments without time-consuming conversions.

Small lipsticks require different handling techniques than large shampoo bottles. Modern packaging systems feature adaptable gripper systems and variable transport speeds. Gentle product handling prevents damage to sensitive surfaces and preserves the quality of high-end cosmetic packaging.

Format changes are made using stored programmes with precise machine settings. Operators can switch between different product configurations without having to make manual adjustments. This automation reduces sources of error and significantly speeds up production changeovers in the cosmetics industry. In addition, modular machine concepts allow for later expansion to accommodate new product formats or increased capacity requirements.

Customised solutions with a packaging machine for the cosmetics industry from Bagmatic

Every cosmetics manufacturer has specific requirements for its packaging processes. Customised solutions take these special needs into account and optimise the entire production chain. Tailor-made system configurations integrate seamlessly into existing production lines and respect spatial conditions.

Consulting begins in the planning phase with a detailed analysis of the product range and production requirements. Experienced engineers develop tailor-made concepts that take both current and future requirements into account. A packaging machine for the cosmetics industry is validated through prototyping and test runs before final implementation.

Training and support ensure a smooth start to production. Technical personnel learn how to operate and maintain the systems optimally. Continuous service and spare parts supply ensure long-term productivity. Remote diagnostic systems enable rapid fault analysis and reduce on-site service calls.

Cosmetics packaging machine for various product shapes

The variety of cosmetic product forms places high demands on modern packaging technology. A versatile cosmetic packaging machine handles liquid serums, pasty creams and powdery foundations with the same precision. Different dosing methods such as piston dosing, peristaltic pumps or screw dosers are suitable for different product consistencies.

Temperature control plays an important role in the processing of temperature-sensitive cosmetic products. Heated or cooled product containers maintain the optimum processing temperature. Viscous products are easier to dose at higher temperatures, while other formulations require cooling to preserve their structure.

Closure methods vary depending on the product type and packaging design. Pump dispensers for lotions require different assembly techniques than screw caps for creams. A cosmetic packaging machine automatically switches between different closure systems, ensuring consistent tightness. Quality checks verify that all closures are correctly fitted and automatically sort out defective units.