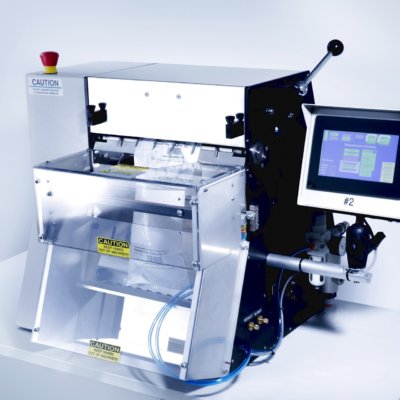

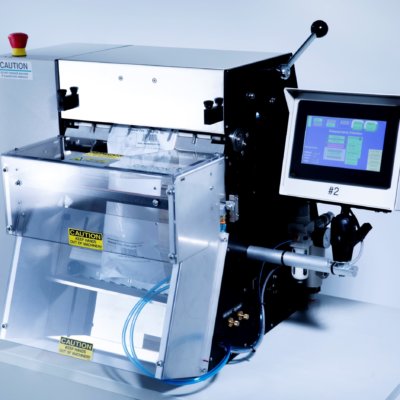

Packaging machines for the fastener industry

BagMatic fastening technology packaging machines pack screws, nuts, dowels, and assembly accessories quickly and precisely into bags on rolls. The fastening industry places special demands on packaging technology, as screws and small parts must be filled exactly according to the number of pieces. Manual counting is error-prone and time-consuming, but automatic systems solve this problem.

BagMatic offers special solutions for the specific characteristics of small metal parts. The neutralization of static electricity prevents parts from sticking to machine components or to each other. This technology makes a decisive difference, especially when packaging galvanized screws or small washers.

Automatic packaging solutions for the fastener industry

The fastener industry works with large product volumes and low margins. Automatic packaging machines reduce unit costs and increase competitiveness. BagMatic knows the requirements of screw manufacturers, hardware dealers, and industrial suppliers from many years of project experience.

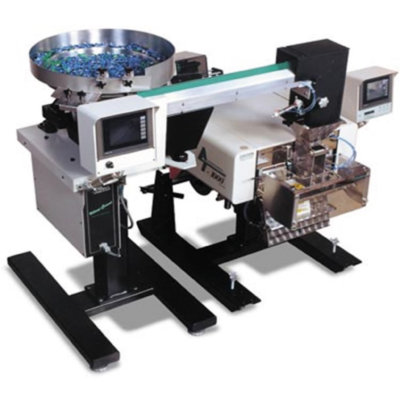

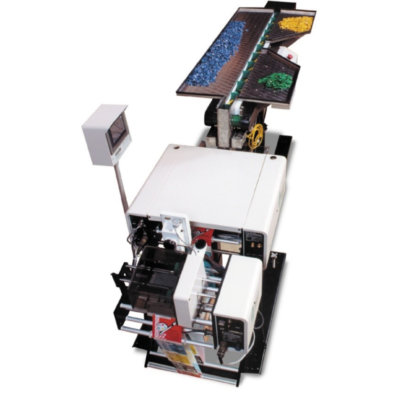

From semi-automatic table-top machines for smaller batches to fully automatic industrial systems with robotic loading, the portfolio covers all production sizes. The entry-level models start at €2,600 and pay for themselves even with moderate packaging volumes thanks to the savings in labor costs.

Integration into existing production lines is carried out according to individual planning. Our engineers create 3D concepts with SolidWorks and simulate the material flow before installation. The feeding technology is configured to suit your screws and small parts, whether vibration spiral conveyors for standard parts or linear conveyors for sensitive surface coatings.

Our packaging machines for the fastener industry

Semi-automatic or fully automatic – horizontal & vertical

Bag materials

Bagmatic offers various packaging options for electrical parts:

- Foil bags

- Flowfresh foil bags

- Twin packs

- Stretch film

- Doyback

Bag properties

- Variable sizes

- Unprinted & printed films & bags

- Fast shipping and storage for bags

- Durable, transparent, robust for heavy parts

- Colored & antistatic film bags, e.g., for electronic components

The BagMatic service for packaging machines

Our services go beyond packaging products. Our trained employees support you in the following areas:

- Repairs & maintenance

- Design & plans

- Assembly & construction

- Comprehensive service & consulting

- Telephone support

- Field service

- Training for customers

Our goal is to provide self-sufficient, fast, and easy bag packaging at a fair price! We strive to offer our customers in the electrical industry complete packaging machines, materials, and solutions, as well as the best possible customer service.

– B. Norman Walter, Manager

Your advantages with Bagmatic and the packaging machines:

- A young, family-owned company in the third generation of packaging specialists

- Competencies in both semi-automatic and fully automatic packaging machines

- Unique "vision system" for quality control and accurate counting of products

- Camera solution for registering the parts to be packed before they are packed in bags

- Unique solution for counting and packaging very small and light parts, e.g. flower seeds

- Robot integration for fully automatic packaging (parts loading)

- Neutralization of static electricity of parts prior to packaging in bags

- Incomparably good customer service both in our house as well as with the customers on site Europe-wide

- Fair and competitive prices

- New and reconditioned machines in stock

Your advantages with Bagmatic and the packaging machines:

- Closing bags made of barrier material

- Closing bags made of polyethylene

- Transport packaging and industrial packaging

- Closing sterile goods packaging

- Welding tubular foils

- Filling and closing at the same time

- Promotional packaging

- Reduce transport volume or oxygen

- Testing flexible materials

Send us a non-binding inquiry now and let us advise you

We are also happy to assist you directly by phone at 02631/4449000 or by email at info@bagmatic.com.

We offer customized packaging machines for your fastening technology

Standard machines work for standard products. However, fastening technology encompasses thousands of different product variants with different properties. M3 screws behave differently in the feed than M12 anchor screws, and wing screws require different bag dimensions than hex nuts. BagMatic adapts each system to your product range.

Customization begins with an analysis of your best-selling item numbers. Which screw dimensions are packaged in which quantities? How do the bag sizes vary? This data is incorporated into the machine configuration and optimizes the packaging process for your specific requirements.

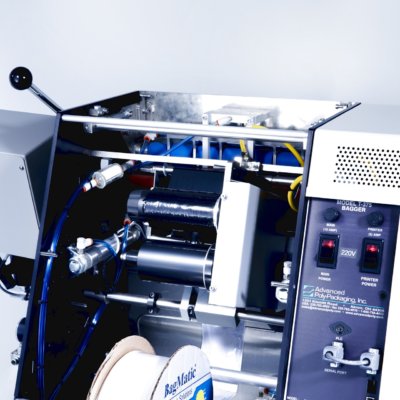

Flexible bag sizes on the same machine enable quick product changes without retooling. The chain bags on rolls are available in different widths and are separated automatically. For different print motifs, the ZEBRA inline printer offers variable data printing with item number, quantity, and barcode.

Reduce manual rework with automatic quality control

Incorrect quantities in the packaging lead to complaints and damage customer relationships. BagMatic’s vision system checks the bag contents before sealing and detects deviations from the target quantity. Incorrectly packaged items are automatically ejected and reworked before they are shipped.

The optical quality control system not only detects incorrect quantities, but also foreign objects and damaged products. An incorrect screw that has accidentally entered the feed is detected and the affected packaging is stopped. This precision eliminates manual spot checks and the associated uncertainty.

To meet the highest traceability requirements, the system documents every packaging process with a photo and time stamp. The QR and barcode bag packaging links the printed code to the quality data. In the event of complaints, the exact packaging process can be reconstructed and analyzed.

Spare parts and service throughout Europe within 48 hours

As an official partner of Advanced Poly Packaging, BagMatic has an extensive spare parts warehouse at its Neuwied site. Wear parts such as sealing jaws, knives, and sensors are immediately available and can be delivered to your location anywhere in Europe within 48 hours if required. This rapid supply minimizes downtime.

Our Europe-wide customer service team will come directly to you in the event of more complex malfunctions. Our service technicians are familiar with the machines from our own production and can solve problems on site. Regular maintenance contracts ensure the availability of your system and extend its service life through preventive inspections.

BagMatic stocks new and refurbished machines. As a third-generation family business, we stand for personal support and long-term partnerships. Contact us for a no-obligation consultation on your packaging solution for fastening technology.