BagMatic, the leader in weighing systems and machines, offers top-of-the-line products that are reliable and durable. From small, medium to large weighing processes, BagMatic offers a comprehensive range of equipment to meet your exact requirements. With decades of experience, BagMatic machines offer the highest accuracy in all types of weighing applications and a simple user interface.

The Ultra-Count series counter UC-2400 is an additional device for counting individual parts and parts of sets. Counting control through a programmable photocell. A touchscreen sends messages about the charging process or malfunctions. It works inline with the T-1000 industrial machine.

With the Ultra-Count ™ series counter you can easily count individual parts or parts of sets. This means that all types of parts (fastening parts, medical parts, electrical parts or other components) can be packed accurately and in a time-saving manner. The UC-2400 offers flexibility and speed to get the job done quickly and accurately.

The UCS-2400 functions as a counter like the serial counter UC-2400, but is also a scale for weight control and a net scale. It is equipped with a large hopper and a vibratory conveyor and is more suitable for fully automatic packaging.

It functions as a partial counter like the standard model UC-2400 and contains a large hopper, a high-speed vibrating bowl made of stainless steel as a drive, a V-conveyor belt for separating the filler parts, an optical high-speed frame and an accumulation device for portioning.

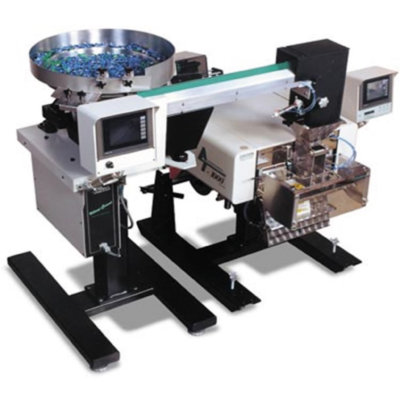

US-5000 semi-automatic weighing / counting system

The Ultrawaage US-5000 is a weighing and counting unit that can be easily connected to the various T-1000 industrial machines and then with an inline function. The device is particularly suitable if you have to / want to quickly change the series of parts or kits to be packed.

The Ultrawaage US 50000 is a semi-automatic weighing / counting system that offers immediate production transitions, set packaging and a variety of order storage.

US-5500 Ultra scale with PTL (Pick-to-Light)

The Ultrawaage US-5500 is a major improvement to the counting and weighing system of the US-5000. On the connected sorting table there are lamps on the compartments for the putty parts to be loaded. With “green” you can still charge, with “orange” no more. This is the "pick-to-light" method.

The Ultrawaage US-5500, together with the T-1000 industrial machine, can pack sets of different parts at a new level: with the help of the superior pick-to-light technology. Loading the kits has never been easier than with the sorting table equipped with LED lamps. When the weights of the portions of the set are entered on the touch screen of the US-5500 at the beginning of the loading, the lamps and the display of the touch screen signal the operator when the target number of a portion of the set has been reached. The next portion of the set (kits) can now be loaded etc. until the target weight of all portions of the set is reached. Only then do all parts of the set (putty parts) fall into the bag, which is automatically sealed and blown off by the T-1000. The loading of the next set can begin. (Portion = number of parts of a part number)

US-9000 Ultra-scale net scale & counting unit

The Ultrawaage US-9000 is both a net scale and a counting unit. It can be easily connected to the T-1000 industrial packaging machine and then works inline. The US-9000 is particularly suitable for small and / or difficult to separate parts that have to be packed.

The US-9000 is ideal for the precise counting of filler parts, which can also be linked together and therefore cannot flow through a part counter. That is why the vibratory bowl feeder offers optimum speed when filling. If the weight of the filled parts approaches the predetermined target weight, the filling speed slows down so that the filling weight deviates only minimally from the target weight. Weighing takes place with a tolerance of up to 0.45 g deviation from the set target weight. If you increase the target weight with the tolerance, you achieve that the desired number of parts is at most exceeded, but never undercut. Therefore suitable

the US-9000 is perfect for light and small parts that cannot be counted on a typical net scale.

T-1000H horizontal industrial machine for packaging

The horizontal industrial machine works like the T-1000, but it can be placed in the correct position, either horizontal or inclined, to facilitate bag loading. See also input accessories and TIZ printer.

The horizontal industrial machine offers countless packaging solutions for a wide variety of products that are difficult to load on the T1000 vertical industrial machine. Insert your product horizontally into the bag - either manually or automatically: the machine then takes care of the rest. It seals the bag at the charging station and unloads the filled bag on the horizontal conveyor belt. The next bag is then already blown open and positioned - ready to receive the next product.