It is a well-known fact that nowadays there is hardly any branch of industry, neither in the world nor in Germany, which does not depend on packaging and makes use of it on a daily basis. A good packaging not only serves to protect your goods, it can also simplify the transport of these and also serve promotional purposes. A vacuum packaging machine, or vacuum packaging machines, has become an indispensable part of the productive and efficient packaging process.

We, at Bagmatic, have made it our mission to support companies with innovative and effective packaging solutions from semi-automatic vacuum packaging machines, to fully automated, multi-part packaging systems.

Bagmatic offers vacuum packaging machines for your company. Please feel free to ask us about this without obligation!

Vacuum packaging machine – Durable and storable packaging

Vacuum packaging machines have already proven their worth for fresh products such as vegetables and meat, but are also being used more and more in warehouse logistics. On the one hand, the product shelf life can be extended, and on the other hand, the contents can be protected from contamination and stored in a space-saving manner. With the help of a vacuum packaging machine, the air is evacuated from the vacuum bag, which then wraps around the product like a second skin and is finally sealed. In this way, the product is sealed all around and protected from external influences. The minimized packaging volume can also help protect the environment by reducing packaging waste while saving valuable storage space. The use of a vacuum packaging machine can thus replace unnecessarily huge cardboard boxes and enormous plastic bags, making products look more attractive and concretely recognizable from the outside.

The vacuum packaging machine and its fields of application

Across industries from the butcher to the textile industry to the medical and pharmaceutical industry, the areas of application are numerous. Whether it is the storage of metal components, coinage or the safe transport of electronic products, with industrial vacuum packaging machines the safety of the goods is always guaranteed. In the medical field, vacuum packaging can shield medical equipment from bacteria, germs and contamination. The use of a vacuum packaging machine can also ensure the hygienic transportation and clean storage of laboratory items. Individual pieces of medical equipment, if necessary, can be stored without difficulty, ready to hand and easily identifiable. Even oxidation and damage to the surface can be counteracted in this way. The vacuum packaging machine is particularly suitable for voluminous items of clothing or textiles whose packaging would otherwise take up a lot of space. In addition, the contents in the vacuum bag can be protected from penetrating moisture and dust particles.

Product safety through the vacuum packaging machine

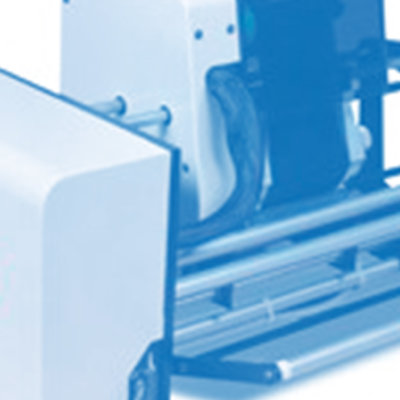

Easy handling with great efficiency. Transport safety and undamaged arrival of the products can be guaranteed with the help of the fixation in the vacuum bag. Commercial and industrial goods can be protected against sharp objects and slipping in the packaging. This type of packaging is therefore particularly suitable for loose small consignments, but also for large individual items, which can thus escape mutual friction. The vacuum packaging machine is the ideal support for the storage and shipment of sensitive items and foodstuffs. The sealing seam makes an important contribution to product safety. In addition to single and double sealing, the option with three sealing seams is the most reliable. With different sealing band lengths, a vacuum packaging machine can seal multiple bags simultaneously without air for optimized productivity. With further accessories such as the liquid separator, even moist products can be vacuumed as well as sealed without any problems.

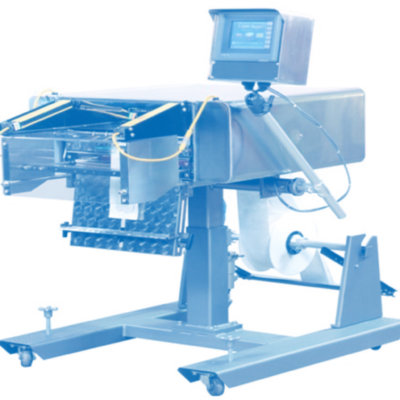

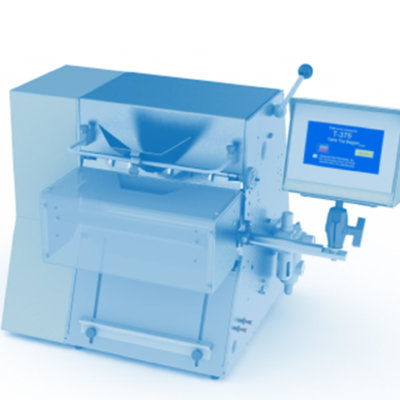

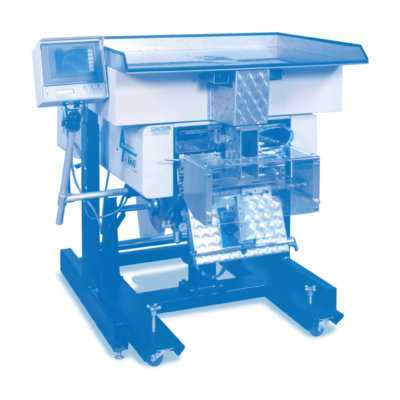

Variations of vacuum packaging machines

The reason for the wide range of possible applications is the combination of specific equipment and bag properties with different thicknesses. Here, the technology and the vacuum pump have a great influence on the range of applications. Whether an automatic, manually operated or semi-automatic vacuum packaging machine is used is also determined by the size and number of goods. Mobile devices and semi-automatic table machines are therefore suitable for smaller parts, the single or double chamber vacuum packaging machine with a connected high-performance vacuum pump, on the other hand, enables the fast as well as airtight packaging of large items. Moreover, the choice of vacuum bags can be adapted to the contents not only in shape and color. For pointed objects, for example, particularly strong vacuum bags with up to 200 µm can be used, while antistatic bags are available for the electronic sector.