Packaging machines – automatic packing machine

Bagmatic exclusively sells the products manufactured by Advanced Poly Packaging ™. We offer you a variety of packaging solutions – from the semi-automatic packaging machines to fully automated, multi-part packaging systems.

If your company has potential customers for whom our products could meet the requirements for foils for packaging bags (Foil bags), pre-opened bags-on-a-roll or semi and fully automatic bag machines, and if you also want to offer our products independently as a dealer, then there is the possibility that we can conclude a contract with you that would be beneficial for both you and us.

Bagmatic offers packaging optimization, with automatic bag packaging, individual bag design, automatic packaging of sets or individual parts – in bags with your logo and bar code. All what you need is packaging equipment for a better process.

Flexible packaging machines are an economic factor because they can promote the durability and handling of each individual product. However, depending on the product, there are also challenges with the respective packaging, which have to be solved. As a packaging machine manufacturer, it is therefore very important that an individual solution is developed for every product, no matter how special.

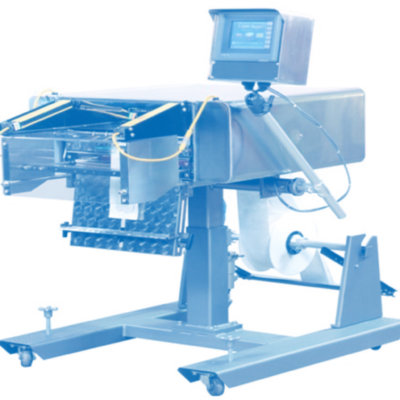

A pouch packing machine ensures productivity, increases efficiency and lowers considerable costs. The packaging machines work automatically, whereby manual operation is not excluded. This technology enables up to 35 bags per minute, avoiding additional work by the printer – labels no longer have to be stuck on by hand, thanks to packaging solutions.

Discover the versatility of our automatic packing machines

You’ll find that our automatic packing machines offer unparalleled versatility, designed to meet a wide range of packaging needs across different industries.

Whether you are in the food sector, pharmaceuticals, or industrial goods, these machines can adapt to various product sizes and packaging formats seamlessly. Our machines feature user-friendly interfaces that allow operators to switch between packaging tasks effortlessly, minimizing downtime and maximizing operational efficiency. The integration of advanced technologies like sensors and IoT capabilities ensures real-time monitoring, enhancing precision and consistency in the packaging process. This not only boosts productivity but also provides valuable data insights for continuous improvement.

By investing in an automatic packing machine, businesses can streamline operations, reduce waste, and significantly enhance overall productivity. These machines are more than just tools; they are strategic assets that contribute to business growth and operational excellence.

The versatility embedded in every machine makes it an invaluable addition to any production line, ensuring you stay ahead in a competitive market.

Why choose our packaging machines for your business?

Opting for our packaging machines means choosing reliability, innovation, and unmatched customer support.

Built to last with high-quality materials and components, our machines ensure longevity and minimal maintenance. We understand the unique challenges faced by different industries, and our solutions are tailored to address these specific needs.

Our commitment to continuous innovation and heavy investment in research and development bring you the latest advancements in packing automatic machine technology. We adopt a customer-centric approach, working closely with you to understand your requirements and provide solutions that enhance your business processes. Additionally, our machines come with comprehensive training and support packages to ensure your team can operate them efficiently from day one.

Environmental sustainability is also a key focus – our machines are designed to minimize energy consumption and reduce material waste. By choosing our solutions, you are not just purchasing a machine; you are partnering with a company dedicated to helping your business succeed and grow.

Increasing productivity with automation when packaging all kinds of products

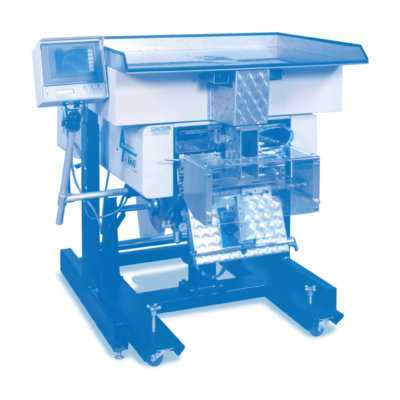

The automated bag packaging increases productivity in the long term. It is completely secondary whether it concerns sets or individual parts, because the automatic solution has a reliable counting system.

Which product it is also not important, because the packaging machines have been developed so that all products can be packed, like industrial packaging or with a home packaging machine. Whether from the food industry, pharmaceutical industry or cosmetic industry. There are no limits for protective packaging with your products. A sealing machine helps also with seal packaging.

Another component of automation is packaging technology optimization, which enables the printing of a logo with a barcode. No further manipulation is necessary. In the packaging equipment you can also find a small packaging machine and price.

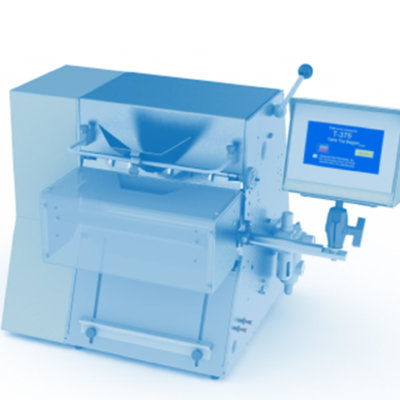

Experience shows how important low maintenance is. There is a four-color touchscreen display on the popular and vertical packaging machine T-375, which also communicates errors. But also when changing roles is necessary. Thanks to an intelligent design, this maintenance is completed within a minute. (or use horizontal packaging machine).

Our products are designed so that hardly any understanding of technology is necessary. The touchscreen provides further information, such as that the end of a run has happened.

Choosing the right packaging machine for your needs

Selecting the right packaging machine for your specific needs is a crucial decision, and we simplify this process with expert guidance and a diverse range of options.

Our extensive portfolio includes machines tailored for various applications, ensuring a perfect fit for every requirement. Whether you need a high-speed automatic packaging machine for bulk products or a specialized solution for delicate items, we have you covered.

Our team of experts will work closely with you to assess your production needs, space constraints, and budget, recommending the most suitable machine for your operations. Customizable features allow you to adapt the machine to future needs, ensuring long-term value. With intuitive user interfaces and robust construction, our machines are easy to operate and maintain, providing a seamless transition into your production line.

Investing in the right packaging machine from us means improved efficiency, reduced downtime, and enhanced product quality, contributing significantly to your bottom line.

Maximize productivity with our automatic packing machines

Productivity is a critical factor in any manufacturing process and our automatic packing machines are designed to maximize output while minimizing errors and waste.

Leveraging cutting-edge technology and innovative design, our machines operate at peak efficiency. Features such as rapid changeover capabilities, integrated quality control systems, and real-time performance monitoring ensure optimal functioning. By automating repetitive and time-consuming tasks, our machines free up your workforce to focus on more strategic activities, boosting overall productivity.

The precision and consistency offered by each packing automatic machine guarantee that every package meets the highest standards of quality, reducing the risk of returns and enhancing customer satisfaction. Our machines are designed for easy integration into existing production lines, minimizing disruption and ensuring a smooth transition.

With our automatic packing machines, you can achieve higher throughput, lower operating costs, and a significant competitive advantage in your market.

From small businesses to large enterprises – We have the right pack machine for your requirements

We understand that businesses of all sizes have unique packaging needs, which is why we offer a comprehensive range of pack machines designed to cater to both small businesses and large enterprises.

For small businesses, our compact and versatile machines provide cost-effective solutions without compromising on performance or quality. These machines are easy to operate, require minimal maintenance, and handle a variety of packaging tasks, making them ideal for startups and growing companies.

For larger enterprises, we offer high-capacity automatic packaging machines that deliver exceptional speed and precision, capable of meeting the demands of large-scale production. These machines come equipped with advanced features such as automated material handling, integrated quality control, and data analytics tools for real-time monitoring and optimization.

Regardless of your operation’s size, our machines are designed to be scalable, ensuring they can grow with your business.

By choosing our solutions, you partner with a company committed to providing innovative and reliable packaging solutions that drive efficiency and support your business growth at every stage.

(Sachet packaging machine, bulk packing machine and more).