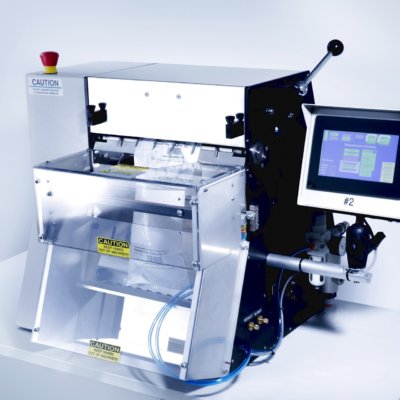

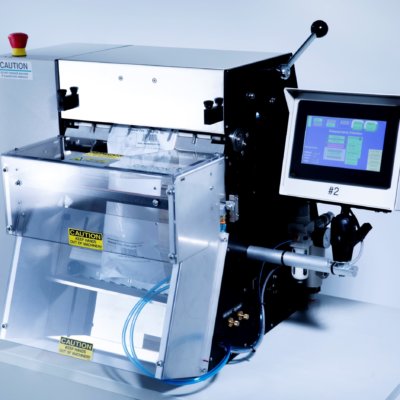

Semi and fully automatic tubular bag table packaging machines

With our bag packaging machines for on the table or worktop, you increase your productivity, simplify the packaging process and lower your packaging costs. There are both table packaging machines and table sealing machines. We offer manual and fully automatic packaging table machines. In manual models, welding is controlled by a foot pedal, and our fully automatic table machines do this for you too.

Our table packaging machines are compact and space-saving. They are available with an integrated printer, so that the additional step of sticking on labels is eliminated. Thanks to the patented “next bag out” technology, the bags are printed continuously. So there can be no confusion, as the bottled product is immediately labeled. This optimization of packaging leads to further time savings.

Table machine for packaging

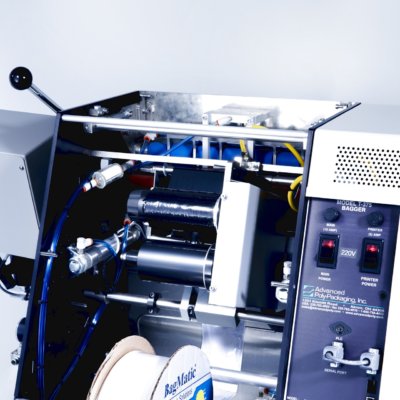

The packaging with prefabricated chain bags on rolls offers an excellent alternative to packaging with tubular bags. The exchange of new rolls with tubular bags takes less than a minute. The integrated bag opener ensures that each bag is also open and can be filled. The bag is moved to the loading position and opened automatically. It can always happen that a bag is not opened properly by the air flow.

Our table machines are very easy to use via the touch screen, which also displays error messages. They work fully automatically and can be connected to any production line. Different settings for the individual throughput cycles can be saved and the number of packaged bags can be easily read. You don’t have to worry about anything else. Universal funnels, which are included in the standard package, are used for filling.

The various table machines for tubular bag packaging

T-375 Table machine with printer

T-300 Table machine with BO-30 bag opener

T-300 automatic table machine and welder

T-275 automatic table machine for packaging

T-200 manual table machine for packaging