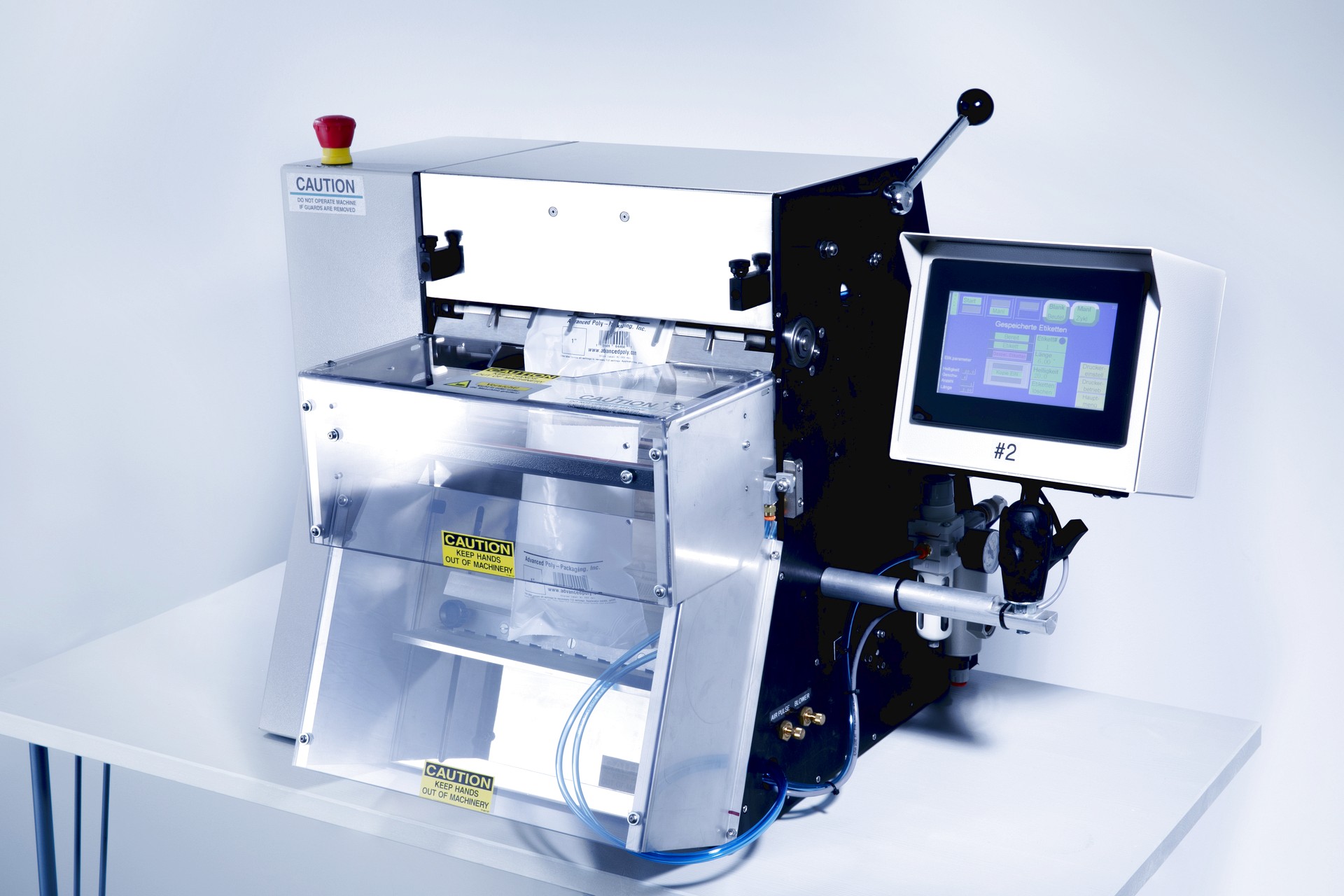

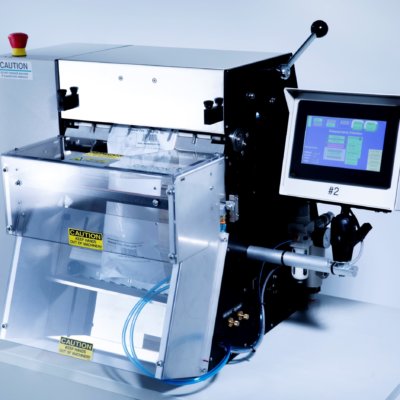

Semi-automatic packaging with the packaging table machine T-375

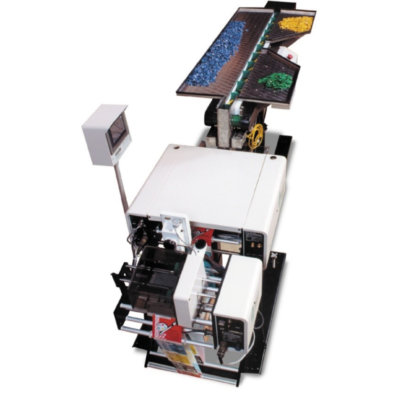

In addition to all the features of the T-30 0, the T-375 offers a printer for continuous bag printing. This patented function enables the bag to be printed immediately before filling, which ensures that your products are labeled precisely. This enables the packaging of large quantities and provided with an article number.

0, the T-375 offers a printer for continuous bag printing. This patented function enables the bag to be printed immediately before filling, which ensures that your products are labeled precisely. This enables the packaging of large quantities and provided with an article number.

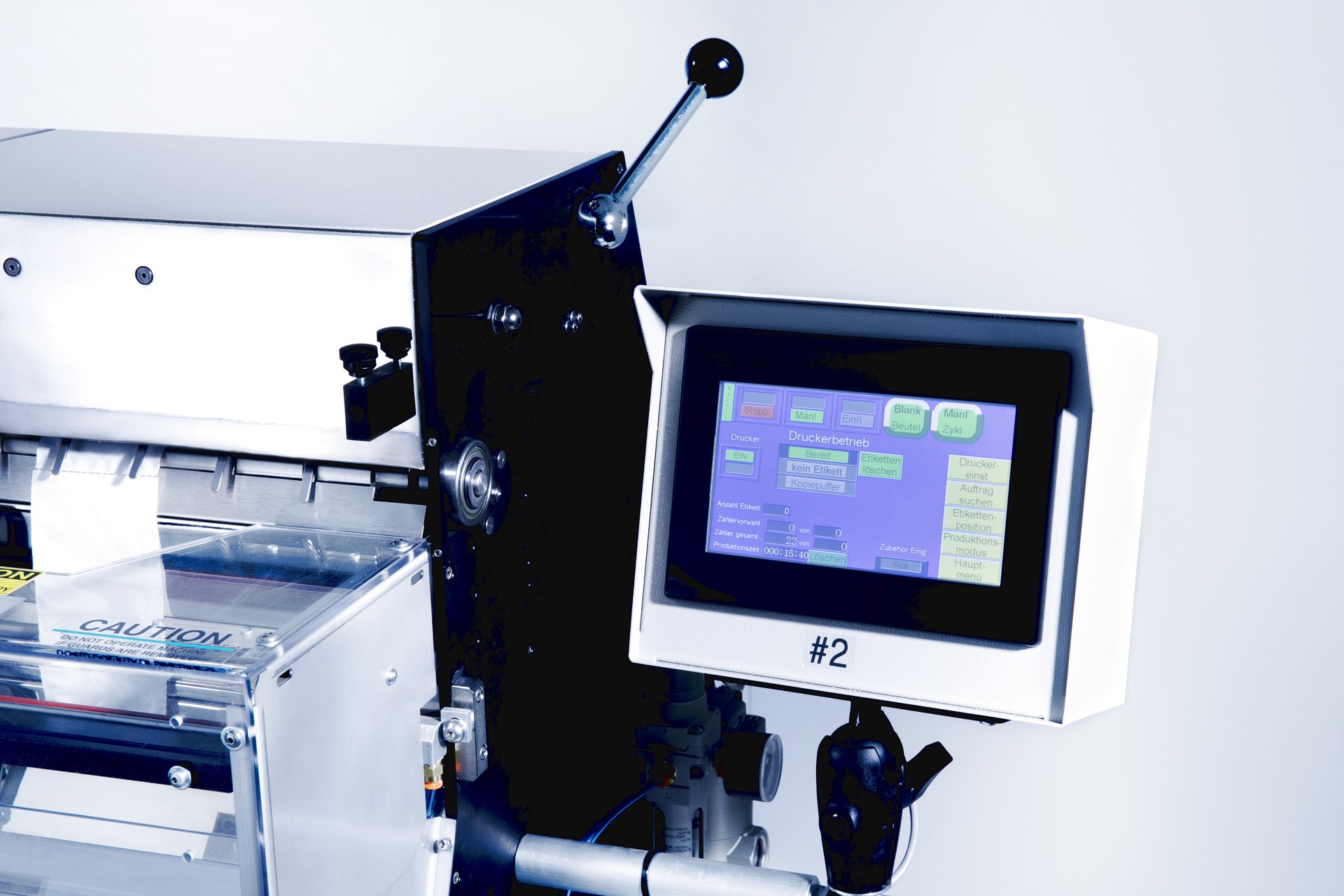

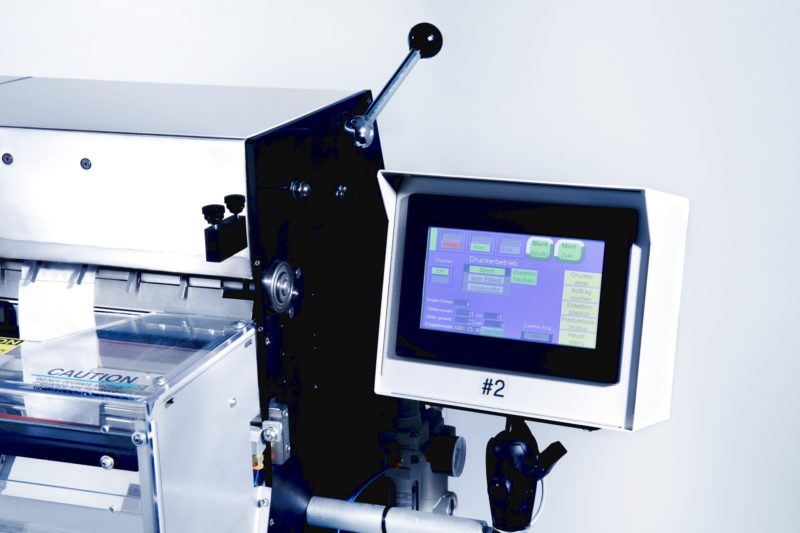

- Four-color screen with pop-up window

- Diagnostic and troubleshooting screens

- Counter to be set in advance and total number indicator

- Universal funnel

- Adjustable filling support

- Fan with flow control device

- One-year parts guarantee

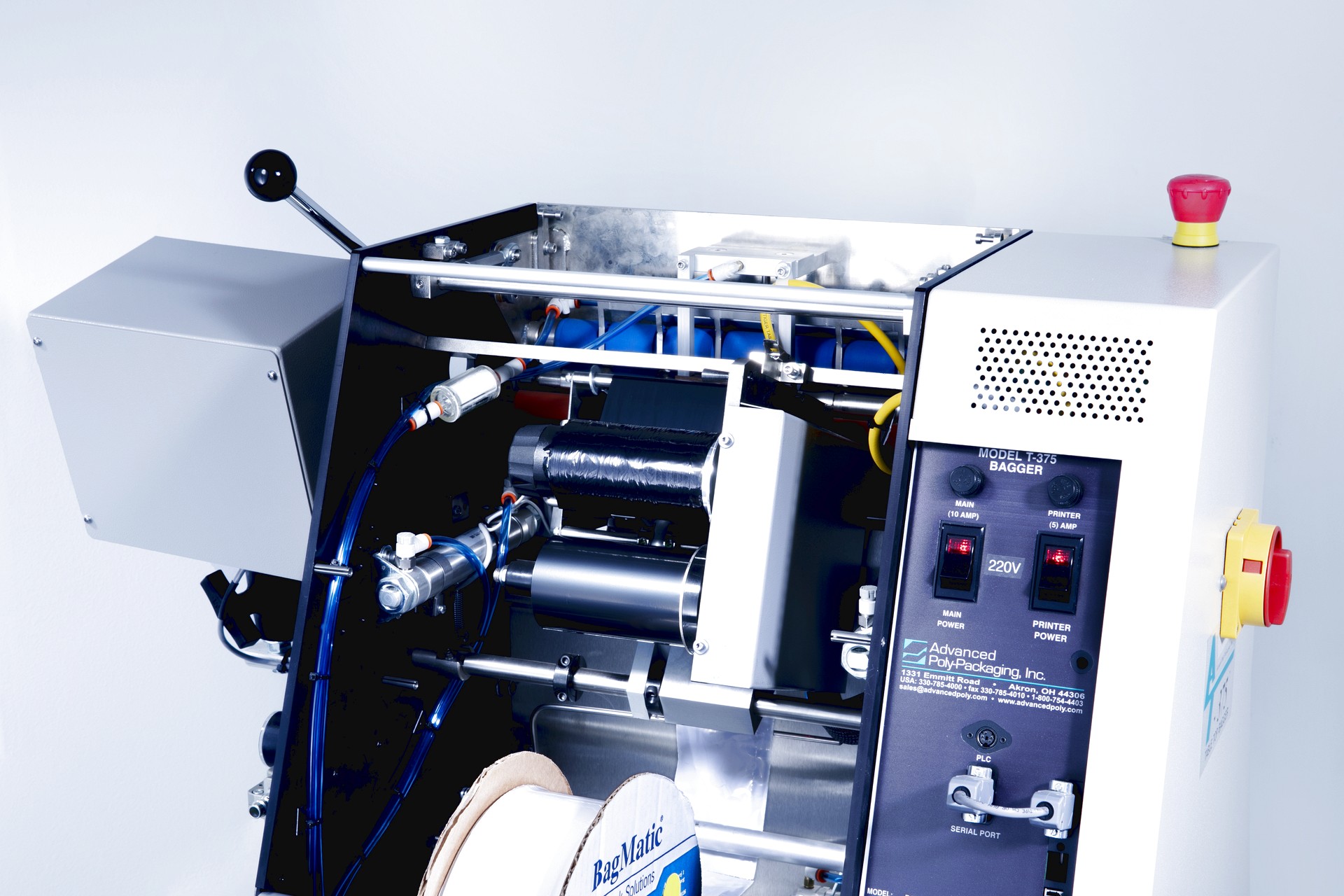

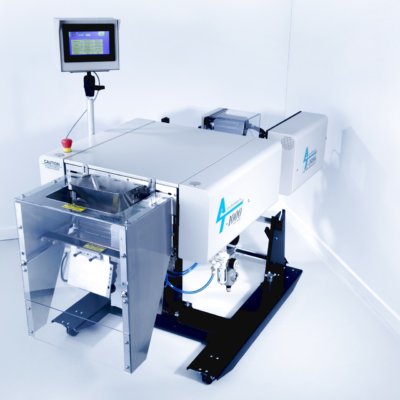

Specifications

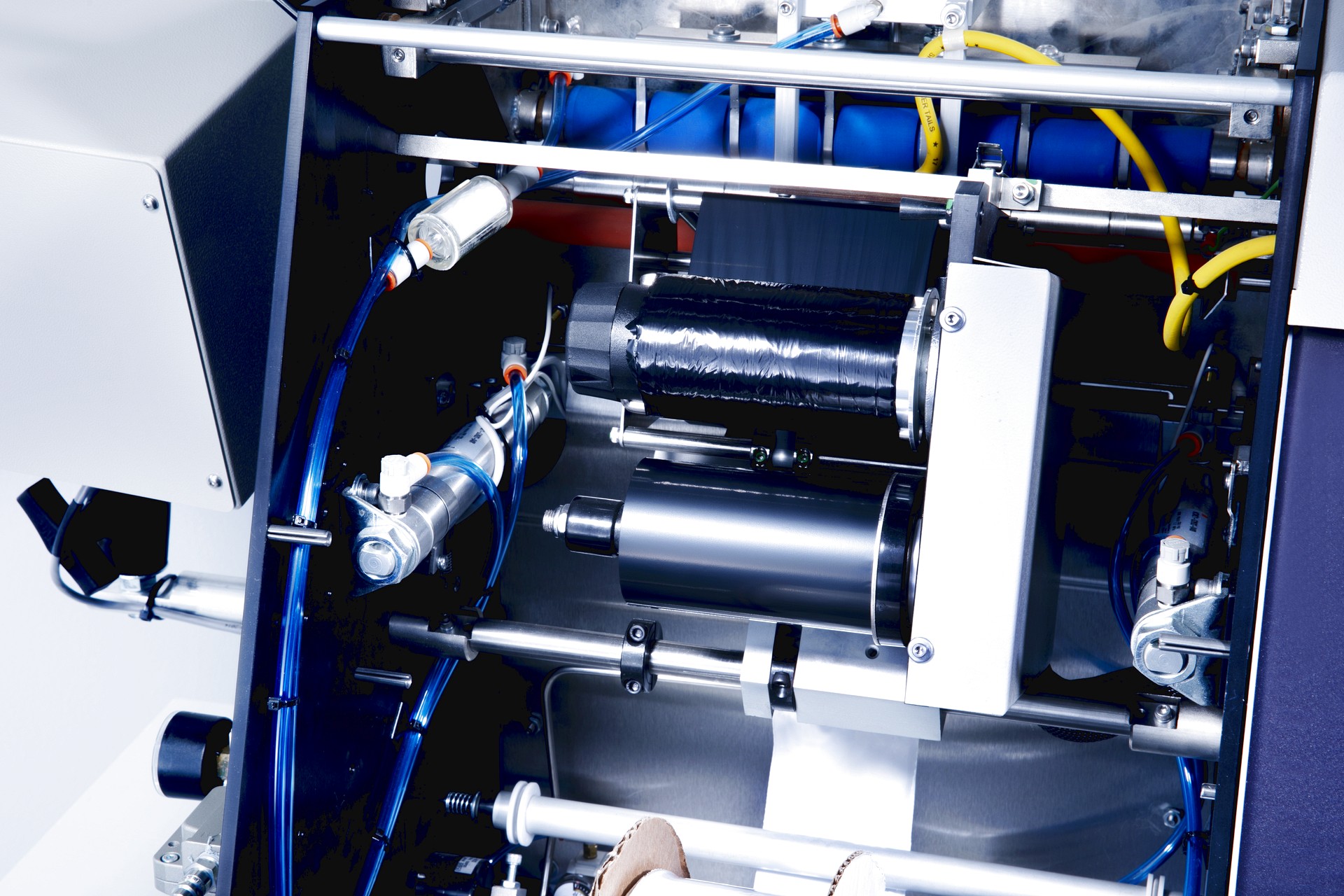

- 3 mm (1/8 ’’) single-wire welding bar (with controlled double thermocouple)

- Dimensions:

Width: 56 cm (22 ’’)

Height 56 cm (22 “)

Depth: 51 cm (20 ’’) - Product passage: 8 cm (3 ’’) (can be enlarged)

- Bag sizes: From 5 cm x 8 cm to 28 cm x 41 cm (2 ’’ x 3 ’’ to 11 ’’ x 16 ’’)

- 203 DPI printer resolution (corresponds to 203 pressure points per 2.54 cm)

- Print width: 10 cm (4 ’’)

- Electricity: 220V / 50Hz

- Air pressure: 60 PSI (corresponds to: 4 bar)

- Weight: 57 kg (125 lbs)