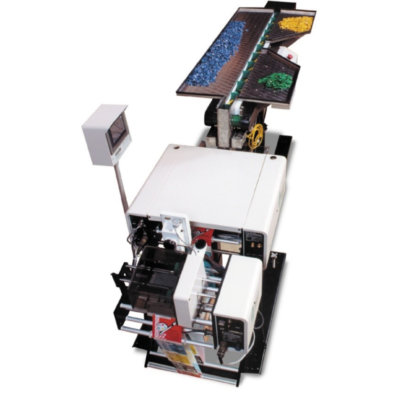

The Ultrawaage US-5500 makes packing kits easier than ever. It is the further development of the US-5000, about which you can find out in the video. But the key improvement is the display for the operator who can work with PTL (Pick-to-Light) technology.

The weights of the portions of the set are entered on the touch screen of the Ultrawaage US-5500, e.g. the weight of fifty screws, the weight of three plugs etc. – up to eight different servings. The parts for the portions are in countless large numbers in the sections of a sorting table. Each section is equipped with an LED lamp. The batch portions are now loaded at great speed: in sequence from section 1 to section 8, the parts in the sections are pushed into a two-chamber funnel on the sorting table – until the LED lamp of the individual section of switches green to orange. Then the desired number of kit portions has been reached and the portion in the first chamber of the funnel is emptied into the second chamber. Weight tolerance for each individual portion: 0.45 g. It happens that the number of loaded parts of a section exceeds the target number of the portion. Then a STOP message appears on the touch screen, which means that some parts of the section must be removed from the first funnel chamber until the STOP message on the touch screen disappears and the content of the first chamber of the Funnel is emptied into the second chamber. Only then does the loading of the following portion of the set (kits) from the next section continue with green LED light. (This is the superior pick-to-light technology).

If all LED lamps light up orange, the contents of the second funnel chamber automatically fall into a bag that the T-1000 industrial machine has already moved into the loading position. The bag is automatically sealed and blown off. The desired set (kit) is ready.

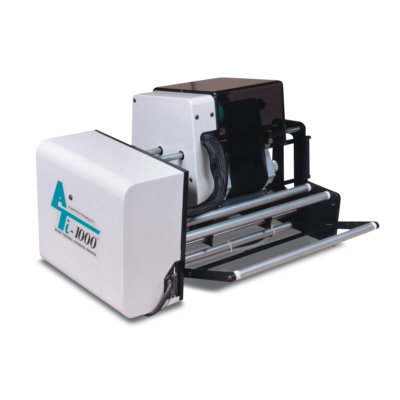

Specifications:

Description: US-5500 with PTL for counting by weighing

Weight: 175 lbs (79.4 kg the scale only)

Dimensions: 35 “x 28“ (L 889 mm x W 711 mm)

Weight tolerance: up to 0.45 g per serving

Speed: up to 30 weighings per minute, depending on the operator

Loading height: adjustable from 36 “to 46“ (914 mm to 1168 mm)

Load cell: 5, 10 or 20 lbs (2.3, 4.5 or 9.1 kg)

Loading capacity: up to 5 lbs (2.3 kg) standard

Update rate: up to 10 times per second

Opening of the scale: 3.75 “L x 6.25” W (L 95.25 mm x W 158.75 mm)

Current: 110/220 V, 60/50 Hz