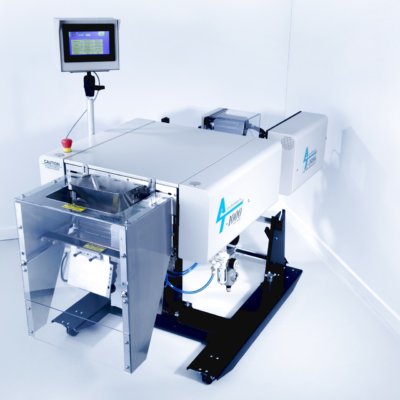

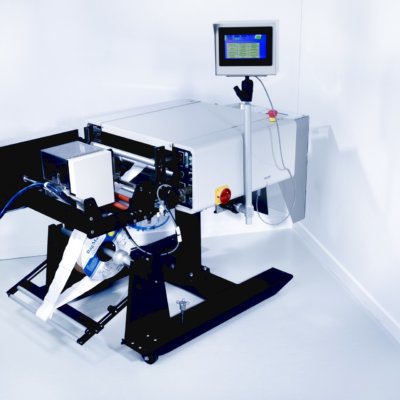

Throw away your hand sealing device and pack your products at least twice as fast with the T-200 table machine. In addition to faster bag packaging, the packaging process is simplified and you reduce costs.

You can pack electronic components, literature, manuals, various groceries, jewelry, hand tools and much more with the T-200 much faster than with the handheld device by using our pre-opened chain bags on rolls instead of loose bags. Pull the bag by hand into the loading and sealing position, then it is immediately opened for loading by an air stream. Fill in your products and operate the foot switch or the safety switch so that the machine automatically seals the bag. As simple as that.

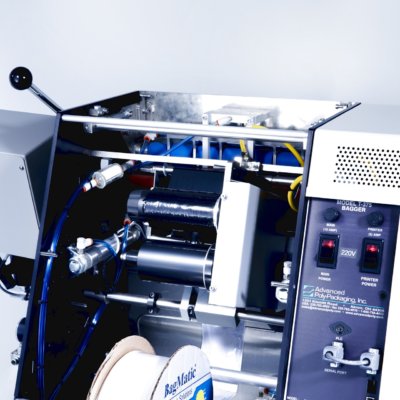

Standard Features:

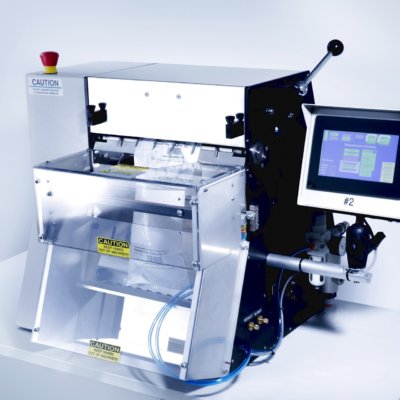

- Dwell time and heat control

- Warm / linger & cold LED lamps indicate the cyclical operation of the welding mechanism.

- The patented Teflon bar greatly improves the durability of the Teflon because the Teflon only comes into contact with the heating element during welding; the heating element remains clean and therefore has a long service life.

- Foot pedal to activate the machine

- The patented anti-interference device ensures that no disturbing objects are welded.

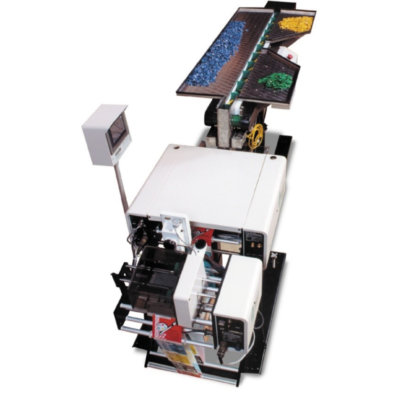

- The universal funnel additive as standard allows the operator to slide the product directly into the bag.

- The adjustable air volume regulator filters a steady flow of clean air with a 4-micron filter.

- The adjustable loading board supports the bag and makes it easier for the operator to bring the bag into the correct sealing position.

- The device for quickly changing the bag rolls and for quickly threading the bag chain allows the operator to change the bag rolls in less than a minute.