The Ultrawaage US-5500 is a major improvement to the counting and weighing system of the US-5000. On the connected sorting table there are lamps on the compartments for the putty parts to be loaded. With “green” you can still charge, with “orange” no more. This is the "pick-to-light" method.

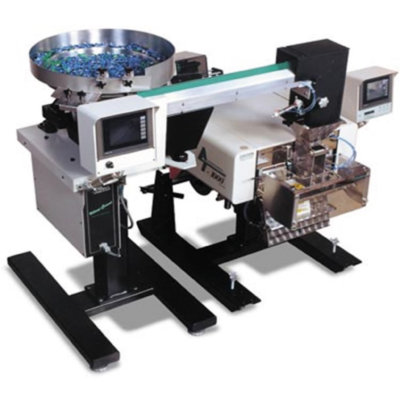

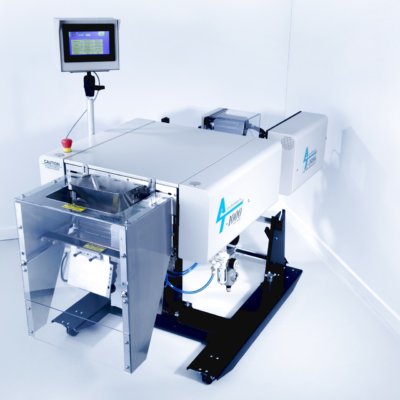

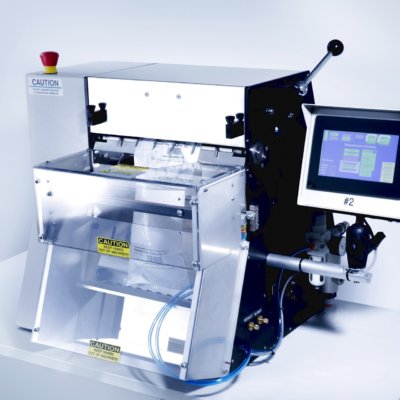

The Ultrawaage US-5500, together with the T-1000 industrial machine, can pack sets of different parts at a new level: with the help of the superior pick-to-light technology. Loading the kits has never been easier than with the sorting table equipped with LED lamps. When the weights of the portions of the set are entered on the touch screen of the US-5500 at the beginning of the loading, the lamps and the display of the touch screen signal the operator when the target number of a portion of the set has been reached. The next portion of the set (kits) can now be loaded etc. until the target weight of all portions of the set is reached. Only then do all parts of the set (putty parts) fall into the bag, which is automatically sealed and blown off by the T-1000. The loading of the next set can begin. (Portion = number of parts of a part number)