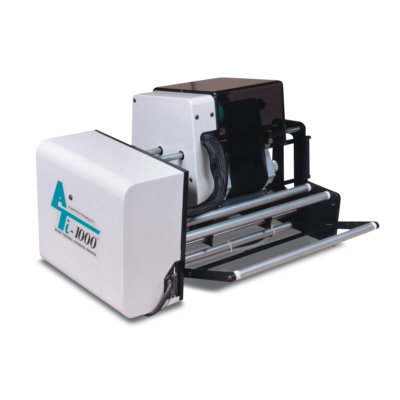

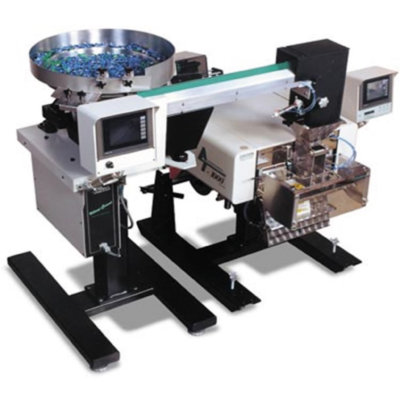

The BÖ-30 is a bag opener that was only available for the T-1000 industrial machine until April 2014 (see PDF file accessories for the T-1000 under industrial machines), but has now also been designed for the T-300 table machine.

You will surely ask yourself why a bag opener is required if the individual bags in the bag chain are moved into the loading position and opened there with the help of an air stream. That is correct in principle, but it happens in rare cases that a bag does not open despite the air flow. If the bag is loaded manually, this would not be a problem, because then you just fill the next bag and do not try to fill the unopened bag.

With automatic loading, however, there must be 100% certainty that every bag can be loaded without exception, and this is achieved by the BÖ-30 bag opener.

The following film shows the bag opener only with manual operation. A video showing the T-300 with bag opener as a fully automatic packaging machine will follow shortly.