Pill Packaging Machines by Bagmatic

There are many regulations and laws governing the use of tablet packaging machines in the pharmaceutical industry. It is important that you have a partner at your side who holds all the necessary certifications and can meet all the required quality standards. The requirements for shipping and packaging sterile tablets can be particularly challenging.

The labelling and protection of tablet packaging are particularly important. Modern tablet packaging machines must comply with the highest hygiene standards and ensure complete traceability. This is the only way pharmaceutical companies can ensure that their products meet regulatory requirements.

Tablet packaging machines for the pharmaceutical industry

The special requirements of medical care and the associated tablet products demand strict compliance with regulations and a perfect process solution for logistics and packaging. Quality and professional handling of tablet packaging machines are a must at all times. As a specialist in packaging solutions, Bagmatic offers you tailor-made tablet packaging systems and outstanding advantages.

- Individual principles for long service life cycles

- High quality workmanship and materials

- Modular systems

- Innovative technologies

- Easy upgrades possible

- Comprehensive service

Our packaging machines for tablets

semi-automatic or fully automatic – horizontal & vertical

Bag materials

Bagmatic offers various packaging options for electrical parts:

- Film bags

- Flowfresh film bags

- Twin packs

- Stretch film

- Doyback

Bag properties

- Wide range of sizes

- Printing options for films and bags

- Stock clearance sale for bags

- Durable and robust for heavy parts

- Special and customised bag properties available

The BagMatic service for packaging machines

Our services go beyond the products. Our employees support you in the following areas, among others:

- Repairs

- Design

- Assembly

- Consulting

- Telephone support

- Field service

- Training

Our mission is to offer tablet packaging machines and innovative solutions at a fair price! We support our customers in the pharmaceutical industry in implementing, setting up and maintaining self-sufficient, fast and high-quality process and packaging solutions. Modern tablet packaging systems from Bagmatic enable you to achieve efficient production while maintaining the highest quality standards. Our tablet packaging machines are specially designed to meet the requirements of pharmaceutical companies and offer maximum reliability in continuous operation.

– B. Norman Walter, Manager

Your advantages with Bagmatic and the packaging machines:

- A young, family-owned company in the third generation of packaging specialists

- Competencies in both semi-automatic and fully automatic packaging machines

- Unique "vision system" for quality control and accurate counting of products

- Camera solution for registering the parts to be packed before they are packed in bags

- Unique solution for counting and packaging very small and light parts, e.g. flower seeds

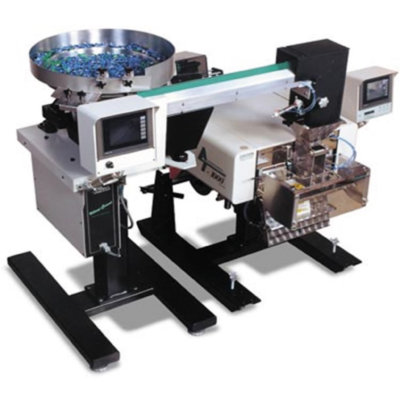

- Robot integration for fully automatic packaging (parts loading)

- Neutralization of static electricity of parts prior to packaging in bags

- Incomparably good customer service both in our house as well as with the customers on site Europe-wide

- Fair and competitive prices

- New and reconditioned machines in stock

Your advantages with Bagmatic and the packaging machines:

- Closing bags made of barrier material

- Closing bags made of polyethylene

- Transport packaging and industrial packaging

- Closing sterile goods packaging

- Welding tubular foils

- Filling and closing at the same time

- Promotional packaging

- Reduce transport volume or oxygen

- Testing flexible materials

Enquire now with no obligation and let us advise you.

We are also happy to assist you directly by telephone on 02631/4449000 or by email at info@bagmatic.com.

Pill Packaging Machine for Pharmaceutical Applications

Pharmaceutical companies face particular challenges when it comes to safe and hygienic packaging of their pills. A professional pill packaging machine must meet the highest quality standards while operating economically. Modern pill packaging equipment ensures compliance with strict hygiene regulations while providing flexibility for various pill sizes and packaging formats.

The requirements for precision and reliability are particularly high in the pharmaceutical industry. Contamination protection and traceability play a central role in selecting suitable packaging technologies. High-quality materials and precise dosing systems ensure consistent product quality and minimize waste.

Bagmatic offers specially developed solutions that meet the regulatory requirements of the pharmaceutical industry. Our systems integrate seamlessly into existing production lines and enable complete documentation of all packaging processes.

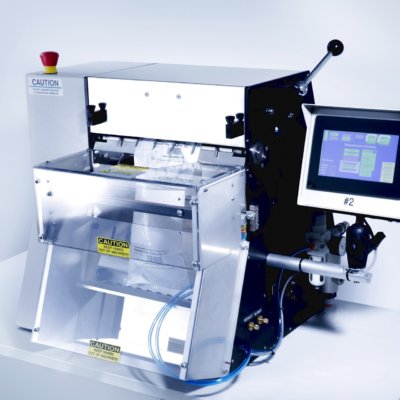

Professional Pill Pack Machine Systems by Bagmatic

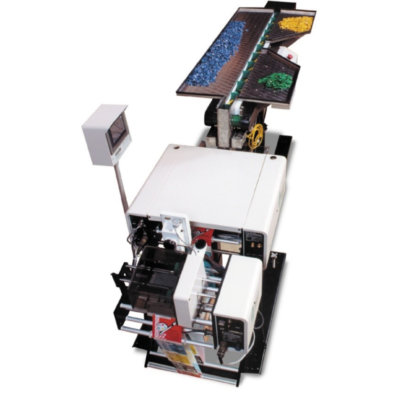

Complete pill pack machine systems offer you the opportunity to optimize your entire production line. These integrated solutions connect various packaging steps and create efficient workflows. From automatic dosing to final labeling, all components work synchronously together.

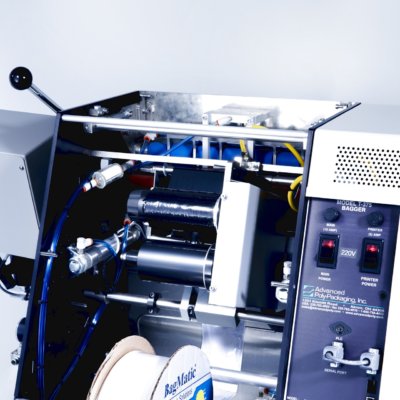

Bagmatic exclusively distributes proven technologies that have proven particularly reliable in practice. Our pill packaging equipment is characterized by its modularity and can be adapted to specific production requirements. Both semi-automatic and fully automatic configurations are available.

The advantages are clear: reduced personnel costs, minimized error rates, and significantly increased production capacities. At the same time, our systems enable precise portioning and ensure consistent packaging quality. Individual bag designs with your company logo and corresponding barcodes are easily realized.

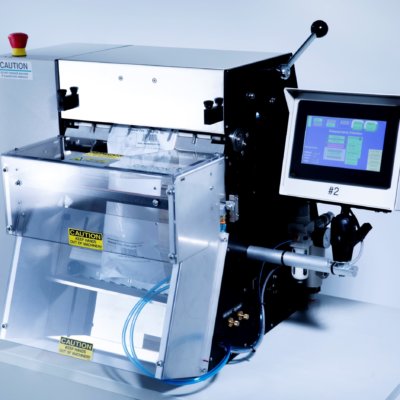

Efficient Automatic Pill Packaging Machine with Individual Adaptation

Every company has specific requirements for its packaging processes. An efficient automatic pill packaging machine must therefore be flexible enough to process various product variants. Adjustable conveyor speeds, variable bag sizes, and exchangeable dosing units enable processing of the most diverse pill formats.

Modern control technology allows quick changeover between different production orders. Recipe management and automatic parameter settings significantly reduce setup times. User-friendly touchscreen control panels simplify daily work and minimize operating errors.

Bagmatic considers your specific production processes and spatial conditions when configuring systems. Compact design and modular construction enable integration even into existing production environments. Maintenance-friendly construction and easily accessible components reduce downtime to a minimum.

Automated Pill Packer Machine for Your Production

Fully automated pill packer machine systems revolutionize modern production processes through their speed and precision. These systems work continuously and achieve packaging performance that would not be realizable manually. Integrated quality control systems monitor every packaging step and ensure constant product quality.

Sensor technology and intelligent control algorithms immediately detect irregularities and initiate appropriate corrections. Automatic bag feeding, precise dosing, and reliable sealing occur without human intervention. Production data is continuously recorded and enables detailed analysis of system efficiency.

Investment in automated packaging technology pays for itself quickly through reduced personnel costs and increased throughput. Bagmatic supports you in selecting the optimal automation level for your specific production requirements. Expansion possibilities for future growth are already considered during system planning.

Reliable Pharmacy Pill Packaging Machine for Large Quantities

Production facilities with high throughput requirements need particularly robust and powerful packaging solutions. A reliable pharmacy pill packaging machine for large quantities must function continuously over multiple shifts without showing quality losses. High-quality components and preventive maintenance concepts ensure minimal downtime.

Bagmatic relies on proven industrial technology that has proven itself in countless production environments. Our pill blister pack machine processes thousands of pills per hour without problems while maintaining the highest quality standards. Redundant safety systems and automatic monitoring functions protect against production failures.

The combination of robust materials, precise mechanics, and intelligent control technology makes our systems the ideal solution for demanding production environments. Long-term availability of spare parts and competent technical support sustainably secure your investment.