Flexible Feeder

The Flex Feeder is unmatched as an input unit. The filler parts flow on a vibrating conveyor belt past sensors, which precisely calculate and determine whether a part is isolated and regular or not. The unit rejects hooked or irregular parts and conveys them back to the separation. Irregular parts are never allowed to be loaded.

Sorting, weighing, counting and organizing automatically

Various machines and topics:

- Multihead weighers

- Weighing systems

- Vibration conveyors

- Counting systems

- Separation systems

- Feeding systems

- Insertion systems

- Pick and place systems

- Robot systems

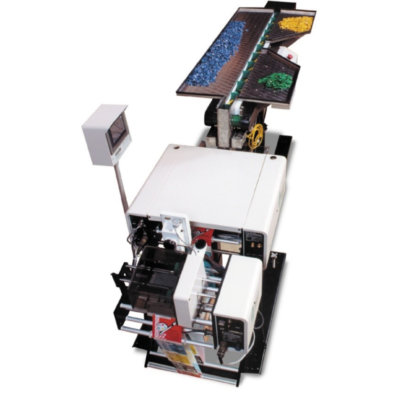

BAGMATIC small parts counting machine for various parts

The Bagmatic small parts counting machine is a universal automatic parts counter for small and irregularly shaped parts, such as:- Finest plant seeds like tomato, patato, carrots etc.

- Vegetable seeds

- Canabis

- Cereals, Corn, Rice, Granola

- Insects, Pupae

- Pharmaceuticals, pills, casules

- Gems, diamonds and precious stones

- Small mechanical parts, spacers, bearings,

- Implants

US-5000 semi-automatic weighing / counting system

US-5500 Ultra scale with PTL (Pick-to-Light)

US-9000 Ultra-scale net scale & counting unit

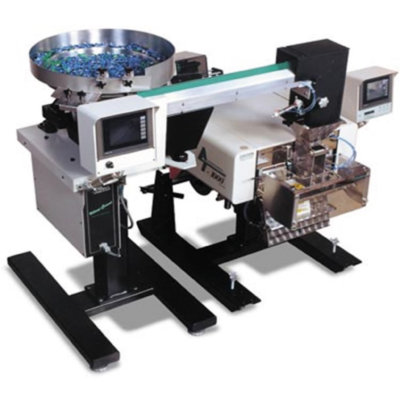

T-1000H horizontal industrial machine for packaging

Feeder machine: our notifications for our costumers

Bagmatic offers a large range of fully automatic feeders for automatic counting and orientation. Vision systems can be added to detect correct parts being feed into the bag, and by using camera technology you can have a very fast setup and changeover time.

Small Parts Feeder:

Are you looking for a small parts feeder for screws, nuts, rubber parts, o-rings filters, anything in the dimension and range starting from 1-20 mm. Bagmatic can help you with this process. We can integrate the feeders with our Bagmatic T375 / The Fastest Bagger in The Market and achive a very efficient packaging and bag printing process.

Send us your reference parts for a free product evaluation, and we would be happy to provide a quote for your attention.

Large Parts Feeders:

Are you looking to feed metal parts, brass, screws, bolts, nuts, or moulded plastic parts, we have a range of different infeed solutions, sizes up to 200 mm.

We offer regular vibration bowl feeders, carpet fedders for delicate and irregular parts, feeders with visoion systems and much more.

If combined with our Bagmatic T1000 bagging machine you get an very efficient and reliable fast solution that will save you money everyday.

Send us your reference parts for a free product evaluation, and we would be happy to provide a quote for your attention.

High Speed Counters:

Are you looking for a parts feeder to count more than 25.000 parts pr. min, then call us now. We have the system you are looking for. Anypart ranging from 1 to 20 mm., can be counted, and bagged with our special high speed counters. Used for moulded parts, filters, screws, nuts, etc.

These system works perfectly with our Bagmatic T1000 machines that have integrated printers

Our counting machines (counters) have counting rates of up to 25,000 objects per minute. This can be achieved for objects as small as 0.5mm and a single system can be configured to handle a wide range of object shapes. Advanced mathematical algorithms ensure 100% accuracy by analyzing multiple views of the falling objects. These counting machines are suited to filters, metal and plastic molds, medical parts, electronic components, o-rings, automotive aerospace, and many more.

Send us your reference parts for a free product evaluation, and we would be happy to provide a quote for your attention.

Feeding technology for packaging machines directly from the manufacturer

At Bagmatic, we develop and produce high-performance systems for automated parts handling that take your packaging processes to a new level. Our feeding technology is based on years of experience in industrial automation and combines mechanical precision with intelligent sensor technology. Vibrating conveyor belts transport your products in a controlled manner for further processing, while integrated detection systems check each individual item.

Separation is carried out reliably by coordinated vibration patterns that automatically return entangled or misaligned parts. This ensures that only correctly oriented components enter the packaging process. Image processing technology supports optical inspection and enables continuous quality assurance from the first to the last production step.

We offer different configuration levels for different requirements. Multihead weighers, counting systems and pick-and-place units can be added on a modular basis. The control technology adapts flexibly to changing product characteristics, which significantly reduces changeover times. You benefit from minimised downtimes and maximum availability of your systems.

Flexible feeding technology optimises your production processes

Modern manufacturing environments require adaptable solutions that can process different product formats without costly conversions. Our flexible feeding technology meets this requirement precisely thanks to intelligent design principles and sophisticated mechanics. Parameters can be adjusted intuitively via touchscreen control panels, allowing format changes to be carried out in a matter of minutes.

The systems automatically detect deviating part sizes and adjust the conveyor speed and vibration intensity accordingly. Robot-assisted components expand the range of functions for complex handling tasks. Grippers and vacuum systems work together precisely to transport even sensitive items gently. This variability makes your production future-proof and competitive.

Easy integration into existing machinery is crucial for economical operation. Our feeding systems communicate with higher-level control systems and merchandise management systems via standardised interfaces. This creates a transparent production chain with complete traceability. You retain control over throughput quantities, reject rates and maintenance intervals at all times.

Precise feeding technology for small parts of the highest quality

The handling of small components places special demands on feeding technology for small parts. Screws, seals, electronic components or medical articles require gentle yet precise separation. Bagmatic has developed specialised systems that reliably orient and position even the finest parts. Vibration conveyors with micrometrically adjustable amplitudes ensure gentle transport without damage.

Camera systems capture each part in real time and compare its position and orientation with stored target values. Deviations are immediately detected and corrected before defective parts enter the packaging process. This optical inspection works with image processing algorithms that identify even minimal defects. Your product quality increases measurably, while complaints and returns decrease.

The separation units adapt to different materials, from plastic to metal to rubber. Different surface properties require adapted conveyor methods, which we achieve with interchangeable conveyor belts. This allows you to process a wide variety of small parts efficiently and economically with a single system.

Error reduction through intelligent sorting and feeding technology

Production errors cause considerable costs due to rejects, rework and delivery delays. Our sorting and feeding technology minimises these risks through multi-layered control mechanisms. Sensors continuously monitor the material flow and detect irregularities as they arise. Entangled parts, duplicates or misaligned components are automatically ejected and fed back into the separation process.

This self-correcting function reduces manual intervention to a minimum. Your employees can concentrate on monitoring activities instead of constantly intervening to make adjustments. The error rate typically drops by over 95 per cent compared to manual processes. At the same time, process reliability increases as human fatigue is eliminated as a source of error.

Weighing systems complement optical inspection with gravimetric verification. Multihead weighers determine precise filling weights and automatically compensate for fluctuations. They easily meet legal requirements for filling quantities and build trust among your customers. The documented measurement data also supports quality audits and certification processes.

Proven feeding technology for complex tasks

Demanding production scenarios require well-designed systems that intelligently link different process steps. Bagmatic offers you sophisticated feeding technology that has proven itself in years of practical use. We cover the entire spectrum, from compact insertion systems to fully automated robot cells. Pick-and-place units operate at cycle rates that far exceed manual processes.

The combination of mechanical robustness and intelligent control technology guarantees long-term availability. Wear parts are standardised and available at short notice, and maintenance work can be carried out during ongoing production. Our service concept includes preventive maintenance as well as rapid troubleshooting. You minimise unplanned downtime and maximise overall equipment effectiveness.

The performance of our systems is particularly evident in multi-component packaging. Different items are separated, counted and fed to the packaging machine in a defined sequence. Synchronisation is carried out precisely via the central control system, which coordinates all subsystems. Contact us for individual advice on your specific application – together we will find the optimal solution for your requirements.