T-1000 Industrial machine with height adjustable AS-10 stand

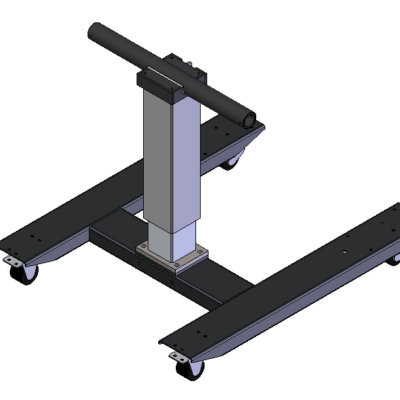

Motorized telescopic stand to adjust the height of the T-1000 packaging machine. This property can be controlled via the touch screen and thus provides an optimal and ergonomic way of working for employees.

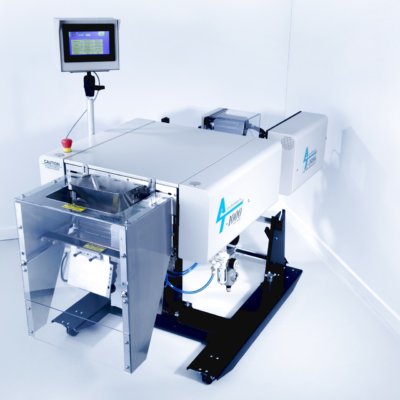

T-1000M Industrial machine for medicinal industrie

The industrial machine T-1000M works like the T-1000 with the main difference that the bag packaging is clinically clean. That is why this machine is suitable for packaging food and for medicine.

The T-1000 industrial machine for packaging contains all the features of the T-1000 including “pop-up” windows, job storage, production graphs and error messages. In addition, it fulfills the necessary conditions for medical packaging, e.g. by using Tyvek® bags with 6.35 mm weld seam and tear-open option.

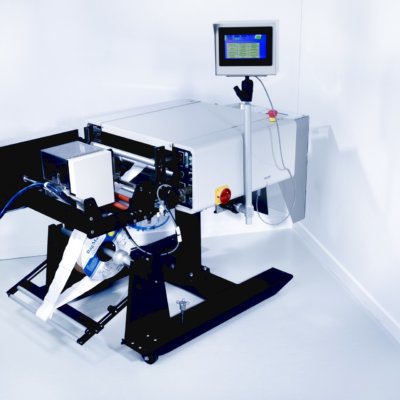

T-1000H horizontal industrial machine for packaging

The horizontal industrial machine works like the T-1000, but it can be placed in the correct position, either horizontal or inclined, to facilitate bag loading. See also input accessories and TIZ printer.

The horizontal industrial machine offers countless packaging solutions for a wide variety of products that are difficult to load on the T1000 vertical industrial machine. Insert your product horizontally into the bag - either manually or automatically: the machine then takes care of the rest. It seals the bag at the charging station and unloads the filled bag on the horizontal conveyor belt. The next bag is then already blown open and positioned - ready to receive the next product.

The industrial machine T-1000 is the heart of the automatic bag packaging. The bags are loaded manually or fully automatically with input accessories. The inline accessories are operated from the machine's touchscreen.

The fastest, simplest and most versatile fully automatic bag packaging machine of its kind with the longest warranty period on the market has become even better. The new T-1000S industrial machine for bag packaging (Advanced Poly-Bagger) with the stepper motor surpasses the old industrial machine T-1000 by far. One reason for this is the interfaces within the machine. Today, the T-1000S offers improved welding registration, fewer components - and therefore less maintenance than before - and quieter, environmentally friendly production.

The packing speed depends on the nature (shape, size) and the number and the variety of the filling parts, the possible imprint. The speed of the operator also plays a role in manual operation. Therefore, only an approximate value can be given.