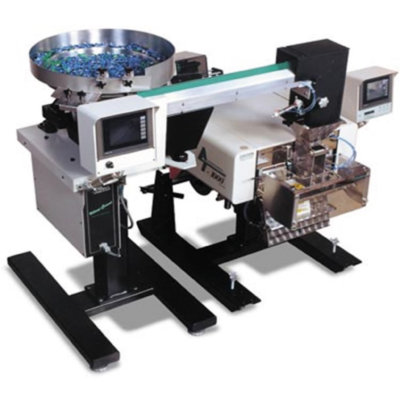

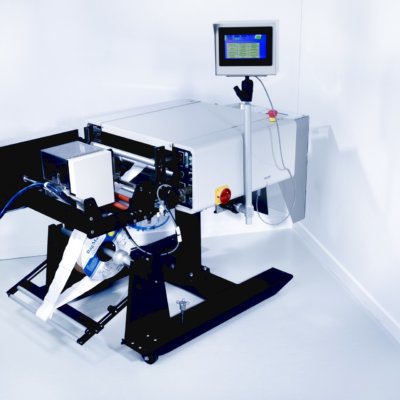

The Ultrawaage UCS-2400 fulfills three functions in one. This has never been seen on the market before. It contains:

1. a vibration part counter

2. a weight control scale

3. a net scale

The functionality of the additional weight control scale is ideal for customers who demand perfect counting. After the portion count has been completed, the scale weighs the portion and accepts or rejects the weight. An automatic auto-correction device is available if the number of filler parts falls below the target weight of the portion.