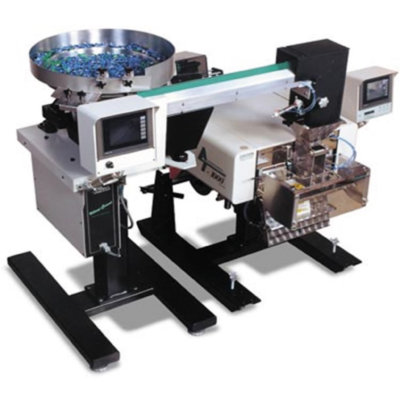

BAGMATIC small parts counting machine for various parts

The Bagmatic small parts counting machine is a universal automatic parts counter for small and irregularly shaped parts, such as:

- Finest plant seeds like tomato, patato, carrots etc.

- Vegetable seeds

- Canabis

- Cereals, Corn, Rice, Granola

- Insects, Pupae

- Pharmaceuticals, pills, casules

- Gems, diamonds and precious stones

- Small mechanical parts, spacers, bearings,

- Implants

All these products have in common that it is difficult and time consuming to count them manually.

Either they are irregular shaped or they are very light or very small. Because of this, the quantification of these parts by weight comes up against limits.

The Bagmatic small parts counting machine is especially suitable for counting such parts precisely in small to medium quantities piece by piece.

Important applications of the Bagmatic small parts counting machine are the repetitive, exact counting of a preselected number of parts or the conventional determination of the 1000 grain weight according to ISO 520. We also offer

seed counter machines for companies

With the Bagmatic small parts counte , parts with diameters from 0.3 mm to approx. 18 mm can be counted. All sizes can be processed with same adjustable conveyor bowl. Different feed containers for differently sized products are not required. A version with an external, larger conveyor, the Bagmatic MAXI, is available for parts with diameters up to 25 mm.

The Bagmatic automatic parts counting machine is characterized by its robust construction and a simple, fool-proof operation. The large, bright LED display is easy to read even in daylight. The count signal is processed by a microprocessor which allows also the detection of parts with particularly difficult shapes. The small parts counter is equipped with terminals for remote control so that it can be combined, for example with packaging and filling machines.

The Bagmatic small parts counting machine is the successor of our previous model 580, which was produced from 1980 for about 25 years. The new Bagmatic parts counting machine combines modern electronics with the proven key components that were already responsible in the previous model for long durability and unmatched accuracy. The Bagmatic piece counting machine can be described with attributes such as longevity, durability, robustness and reliability – this for many years.